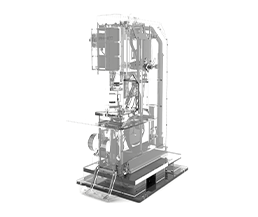

Nargesa 50KG Power Hammer

The Power Hammer PH50 with compressor incorporated, Manufactured to meet the needs of large and small forgings . It's got 50 kg stroke.

Power Hammers PH50 Nargesa, are manufactured in welded and mechanized steel sheet. It is used in many blacksmith workshops to make all kinds of forging, which eases the job of moulding hot steel. Different tooling are used with it to inlay, mould, give shape, cut, pierce, rivet and emboss, etc all kinds of metal. In collaboration with some of the best blacksmiths in Spain, France and the United States, the Prada Nargesa engineers have designed a power hammer with all sorts of new advances in comparison to the other drop hammers on the market up until now. Easier to manage, more precise, safer, quieter and with no need for any civil engineering work for installation in addition to many other features, it’s the best choice available. All Nargesa products are adapted to the CE standards for the manufacture of industrial machinery.

Before purchasing a Power Hammer...

Before purchasing a power hammer, a few basic details are needed before making a final decision:

BUILT-IN COMPRESSOR: The PH50 power hammer has a built-in compressor. This means, unlike with other brands, no external compressor is needed. A 50 kg or 110 lb power hammer without a built-in compressor would need a 5 HP external compressor.

NO NEED FOR SPECIFIC CIVIL ENGINEERING FOR INSTALLATION: Only 4 holes are needed in a concrete floor to insert the 4 chemical bolts that come with the machine when installing the PH50 power hammer.

WELDED STEEL FRAME: The machine frame is not casted; it’s made of welded and die-cut steel. This reduces the possibility of cracking, as occurs with cast power hammers.

MAXIMUM CONTROLLED DROP PRECISION: We achieved maximum precision with the ability to even close a box of matches or position an egg and collide with it without breaking it.

LAPPED CYLINDERS DESIGNED WITH LOW-FRICTION TECHNOLOGY: The friction between the sleeve and piston is normally mechanical and through steel rings. This causes a risk of seizing up over time.

INTAKE AND EXHAUST MUFFLERS: Two mufflers, on the intake and exhaust, reduce the noise to xx dB.

AUTOMATIC LUBRICATION SYSTEM: The lubrication system on the PH50 power hammer features a completely transparent tank next to the power switch to monitor the level of oil in the container without having to use uncomfortable inspection peepholes.

DOUBLE MECHANICAL STOP PROTECTION: The piston on the front and pedal become completely mechanically blocked in an ideal position to easily and safely change the molds.

COLLECTING AND FILTERING OIL FROM THE AIR: The Nargesa PH50 drop hammer has a tank that collects this mix and separates the two components.

SAFETY. CE MARKING: All of our machines are compliant with EC industrial machinery manufacturing standards.

Technical features

The Drop Hammer PH50 Nargesa works by two cylinders, one at the back and another one at the front which is the one that impulses the stem for the stroke. The motor for the powerhammer moves the rod of the back cylinder or compressor and the compressed air goes to the front cylinder through the valves that control the stroke displacement.

- Built-in compressor.

- Maximum drop precision, controlled via a next-generation valve.

- Welded and die-cut steel frame.

- Automatic greasing system.

- Lapped cylinders designed with low-friction technology.

- Intake and exhaust mufflers.

- No need for civil engineering work or special foundations for installation.

- Automatic inner ventilation.

- Inner tray to collect greasing oil.

- Near-zero maintenance.

- Double mechanical stop protection.

- Height and orientation adjustable protection on the front.

- Drive system pedal protection.

- Electric engine protection.

- Emergency stop.

- CE marking.

- Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

- The power hammer can be moved with a forklift or a lifting hook.

- Great variety of tooling and exchangeable molds.

- Custom-manufactured molds.

Technical Features

- Nominal dropping weight: 50 kg / 110 lb

- Strokes per minute: 240

- Ram range: 180 mm / 7”

- Operating range: 220 mm / 9”

- Maximum round working capacity: 70 mm / 2.75”

- Maximum square working capacity: 60x60 / 2.36”

- Engine power: 4 kW / 5,5 HP

- Electrical voltage: 230/400 V three-phase 50/60 Hz

- Single-phase: 220 V voltage OPTIONAL

- Intensity: 18/10 A

- Weight: 1002kg

- Dimensions: 808x1289x1768mm

The machine is sent completely assembled.