Nargesa H2 Propane Forging Furnace

NEW Furnace for the Artistic Forging Nargesa H2, MORE EFFICIENT, SAFER and 100% RESPECTFUL WITH THE ENVIRONMENT. The Furnace is equipped with one burner to heat the iron and work it: molding, bending, piercing, welding, tempering, forging, shoeing horses...

The new H2 Nargesa propane forging furnace is designed for efficient, safe, and environmentally friendly iron heating. It uses up to 75% less gas and can reach temperatures over 1300ºC, making it more efficient than other furnaces in its category. It includes new safety systems for operators, complies with RD919/2006 regulations, and is certified by the APPLUS Technology Center. The furnace emits less than 0.002% CO and features a natural, recyclable vermiculite coating.

This furnace is ideal for large or small forgings, heating iron until it is malleable for shaping into various items like horseshoes, knives, swords, axes, artistic pieces, sculptures, and wrought iron furniture. It is a cleaner, faster, and more efficient alternative to traditional forges.

Advantages of the Propane Furnace H2 for Forging

Safety: Operator safety is a top priority in the design of all Nargesa machines. The H2 forging furnace includes all necessary safety devices to ensure operator well-being and complies with Spain’s RD919/2006 gas appliance regulations.

Automatic Electronic Ignition: This feature prevents the operator from needing to insert their hands into the combustion chamber to ignite the gas, eliminating the need for tools to generate a spark.

Integrated Gas System: The gas system is built into the furnace structure, protecting components from impacts that could cause damage or leaks.

Combustion Chamber Insulation: Made from 100% natural, compacted vermiculite, this insulation is safe for health and fully recyclable, as it contains no glass fibers or ceramics.

Anti-Return Valve: This valve controls the gas flow direction, preventing it from flowing back to the cylinder.

Thermocouple Safety Valve: This device shuts off the gas flow if the combustion chamber cools due to an anomaly, preventing leaks.

Fuel Consumption: Nargesa furnaces use 75% less fuel, consuming only a quarter of what similar furnaces use. A 35kg LPG propane gas cylinder can power the H2 furnace for 50 hours.

Gas Losses: There is no fuel waste; all propane gas entering the combustion chamber is burned efficiently, thanks to newly designed burners by Nargesa.

Insulating Material: The combustion chamber’s compacted vermiculite insulation is 100% recyclable and waste-free, enhancing the cavity’s heating power to over 1300ºC.

CO Emissions: The furnace emits only 0.002% CO, certified by the APPLUS Technology Center.

- Burner: Two Burners

- Automatic Electronic Ignition: Included.

- Stainless Steel Gas Hose: Prevents collapse and burning, with no expiration.

- Precision Pressure Regulator: With built-in pressure gauge for precise gas pressure adjustment.

- Integrated Bar Support: Adjustable for different material lengths, preventing lateral sliding.

- Material Support Placement: Can be positioned at either entry.

- Needle Flow Regulation Valve: Highly accurate.

- Double Insulation: Compacted vermiculite to prevent heat loss.

- Insulating Flange: Keeps heat inside the combustion chamber.

- Heat Painting: Protects and prevents heat loss.

- Air Flow Regulator: Adjusts for different altitudes to ensure proper gas and air mixture for combustion.

- Temperature: Reaches 1300ºC.

- Adjustable Pressure: From 0.1 to 1.5 Bar.

- Maximum Consumption: 0.70 Kg/h at 1 bar.

- LPG Propane Gas Cylinder: 35kg cylinder powers the furnace for 50 hours.

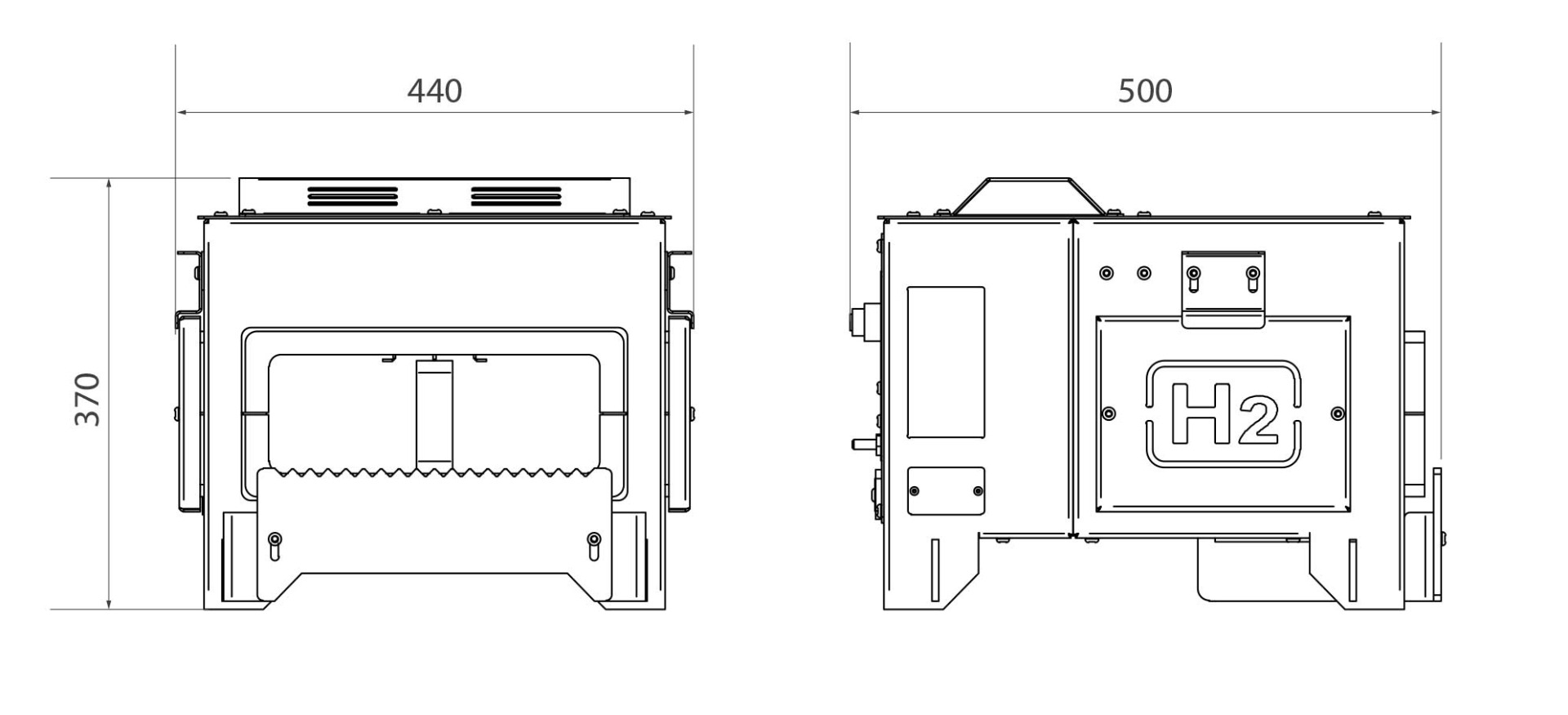

- Internal Cavity Dimensions: 324mm wide x 100mm high x 240mm deep.

- Maximum Material Capacity: Ø 80mm.

- Removable Back Door: For working on the center of iron bars, installed without tools.

- Standard Components: Easy to find in any warehouse or hardware store.